Hand troweled concrete has the uncanny ability to permanently embed and showcase the skill & finesse of the artisans who apply it. The finish has an almost painterly and soft quality that is wholly unique to these types of finishes. Much like Venetian plaster, troweled concrete wears the story of the many hours expended while hand applying the finish. Only; concrete is much tougher, waterproof and in some cases structural. To quote my client; the finished space evokes the impression of “living in a sculpture”.

OSO Industries of Brooklyn NY hand crafted the walls and floor highlighted in this post. To read more articles on this project be sure to check out the first post in the series: Destination Master Bath

Scratch coat:

The scratch coat [shown above] is made up of heavy sand, cement and fibers. The craftsman is applying the mixture over an adhered mesh for added strength [when installed floors].

The scratch coat [shown above] is made up of heavy sand, cement and fibers. The craftsman is applying the mixture over an adhered mesh for added strength [when installed floors].

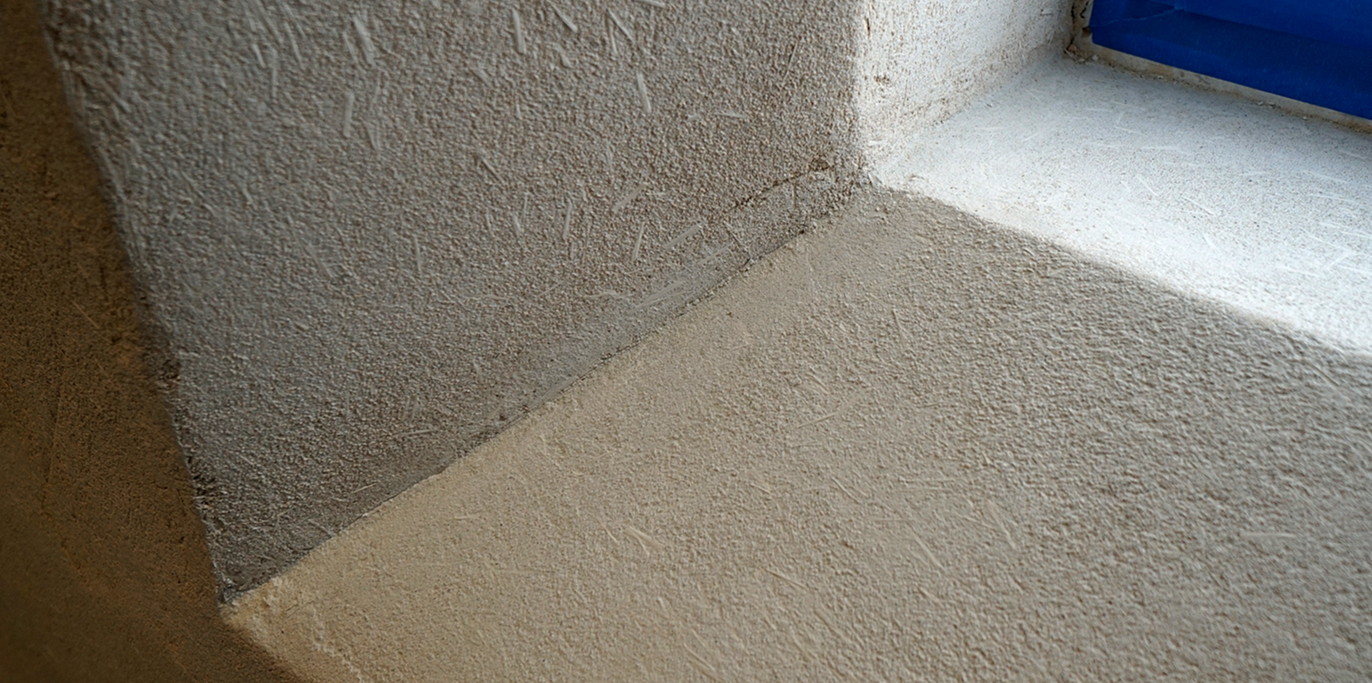

[Above] A close-up of the scratch coat ready to sand and prep for the first color coat.

[Above] A close-up of the scratch coat ready to sand and prep for the first color coat.

An artisan is sanding the scratch coat [above] prior to applying the first layer of pigmented concrete.

An artisan is sanding the scratch coat [above] prior to applying the first layer of pigmented concrete.

Heavy sand & pigment:

The first coat of pigmented concrete is hand troweled onto the scratch-coated wall surface [above].

The first coat of pigmented concrete is hand troweled onto the scratch-coated wall surface [above].

An artisan is sponging [above] the heavily sanded initial color coat, smoothing the surface and exposing the rough sand.

An artisan is sponging [above] the heavily sanded initial color coat, smoothing the surface and exposing the rough sand.

The damp sponging process smooths out the ridges left by the hand troweling process. It also exposes the rough sand creating a surface that the finial coat will readily adhere to [above].

The damp sponging process smooths out the ridges left by the hand troweling process. It also exposes the rough sand creating a surface that the finial coat will readily adhere to [above].

Precision mixing:

The materials for each coat are carefully weighed [above] and mixed into precision batches following OSO’s own proprietary recipe. An artisan will grind the pigments into a fine powder before weighing them into precise batches to ensure color matching.

The materials for each coat are carefully weighed [above] and mixed into precision batches following OSO’s own proprietary recipe. An artisan will grind the pigments into a fine powder before weighing them into precise batches to ensure color matching.

The cream:

Above: an artisan is hand troweling the final coat of “cream” – a mixture of only cement and pigments. The final coat is extremely thin, about the thickness of a piece of paper.

Above: an artisan is hand troweling the final coat of “cream” – a mixture of only cement and pigments. The final coat is extremely thin, about the thickness of a piece of paper.

The craftsman will work and re-work the final coat into an incredibly smooth surface [above].

The craftsman will work and re-work the final coat into an incredibly smooth surface [above].

Above: close-up of the final finish just prior to the sanding, sealing and waxing phase.

Above: close-up of the final finish just prior to the sanding, sealing and waxing phase.

Finally! The astonishing results of the many skilled hours invested in our hand troweled concrete finish. A finish that required five weeks to produce.

Finally! The astonishing results of the many skilled hours invested in our hand troweled concrete finish. A finish that required five weeks to produce.

Be sure to check out the full construction time-lapse video

Sign up below and new posts will be hand delivered to your in box. Stay in the know: